How to make a 6mm planetary gear motor low noise less than 40dB at load

Technical problems in the development of gears and gearboxes are sometimes difficult to make qualitative progress by relying on experience.

Sometimes it is also necessary to look at the analysis and research results of the predecessors.

Plastic gears will deform to a certain extent when subjected to external force. If they are subjected to force for a long time, they will fail, such as tooth wear and broken teeth.

Different plastic materials have different properties.

Different sizes of gears have different characteristics.

Different design methods have different performance.

The only effective method is to use the experimental method to verify the theory. In the test, it is very intuitive to show whether the various performances of the gearbox are excellent.

Compared with foreign countries, domestic gearboxes still have a long way to go. The only way to reduce the gap is to be down-to-earth.

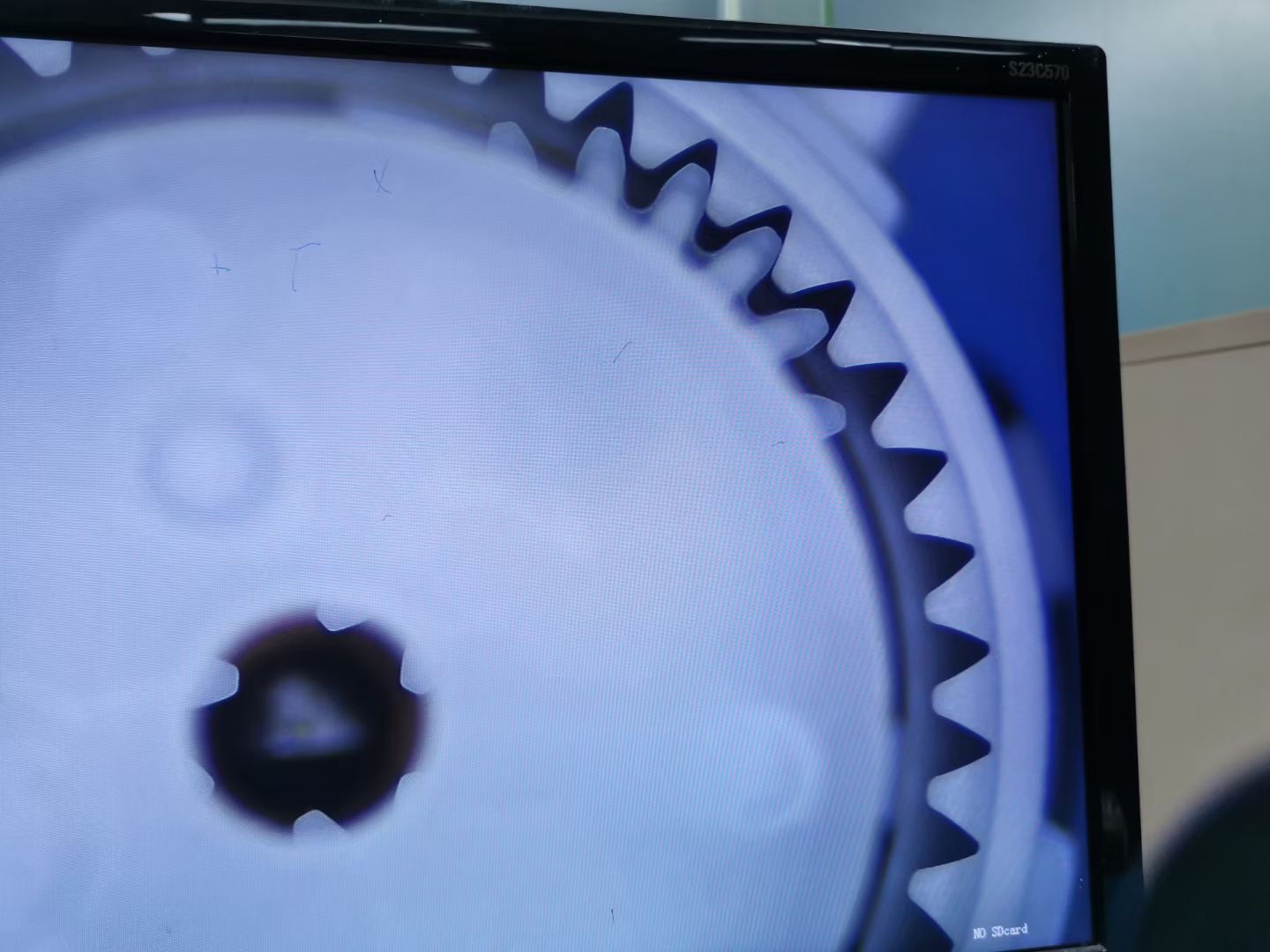

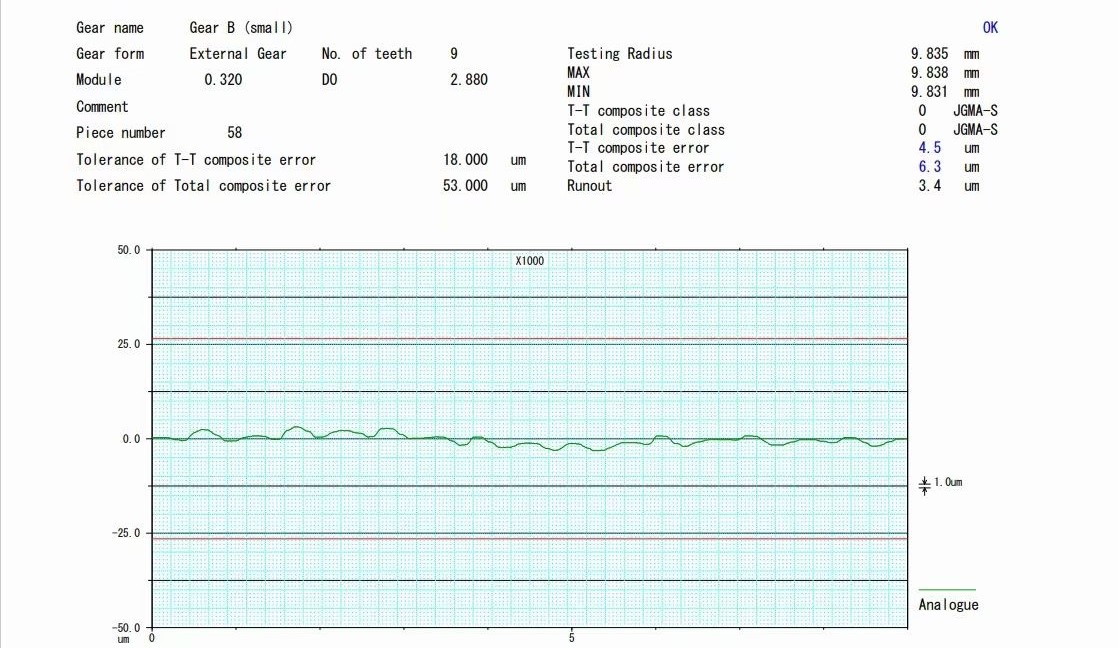

The vibration caused by the pitch deviation is generated along with the gear meshing frequency, and the pitch deviation of the intermeshing gear teeth either reinforces or cancels each other. It is the comprehensive effect of each single error that plays a decisive role in generating noise. The base pitch deviation reflects both the tooth profile inclination deviation ΔfHα (tooth profile angle error) and the pitch deviation Δfpt. When the driving wheel is a standard involute and the driven wheel has a positive base pitch deviation Δfpb, the gear will have an impact when it enters the mesh; on the contrary, when the driven wheel has a negative base pitch deviation, it no longer enters the mesh at the top of the tooth, but at the A certain point in the middle of the gear tooth profile enters into mesh, and the meshing impact is smaller in this case than when there is a positive base pitch deviation. When both the main and passive gears have base pitch deviations, the difference between the base pitch deviations of the main and passive gears can be treated in the same way as the total base pitch deviation, and the elastic deformation of the gear after loading can also be treated as the base pitch error. Our company has widely used this method of paying attention to base pitch error control in gear processing to reduce noise and achieve better results. But also pay attention to the basal section deviation to obtain appropriate. For example, our company has a pair of gears, when the tooth profile inclination deviation fHα of the driving gear is +0.018, and the tooth profile inclination deviation fHα of the passive gear is -0.035, a relatively large noise is generated, and when the tooth profile inclination deviation fHα of the driving gear is adjusted When the rework is +0.005, the noise situation is greatly improved.

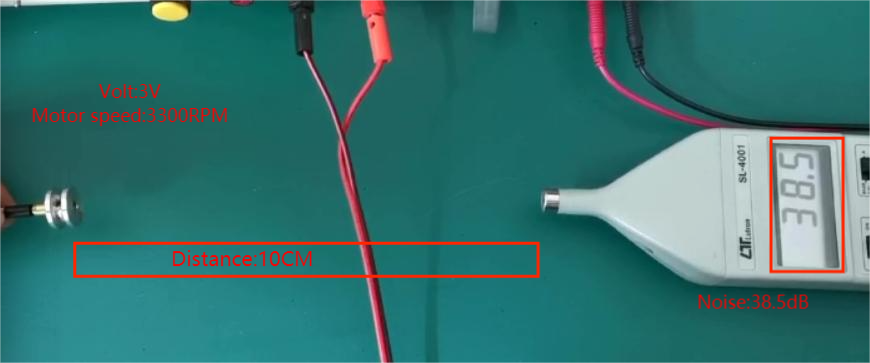

1.6mm gear motor load test noise is less than 40dB

2.6mm plastic gear motor stall torque is 300g.cm

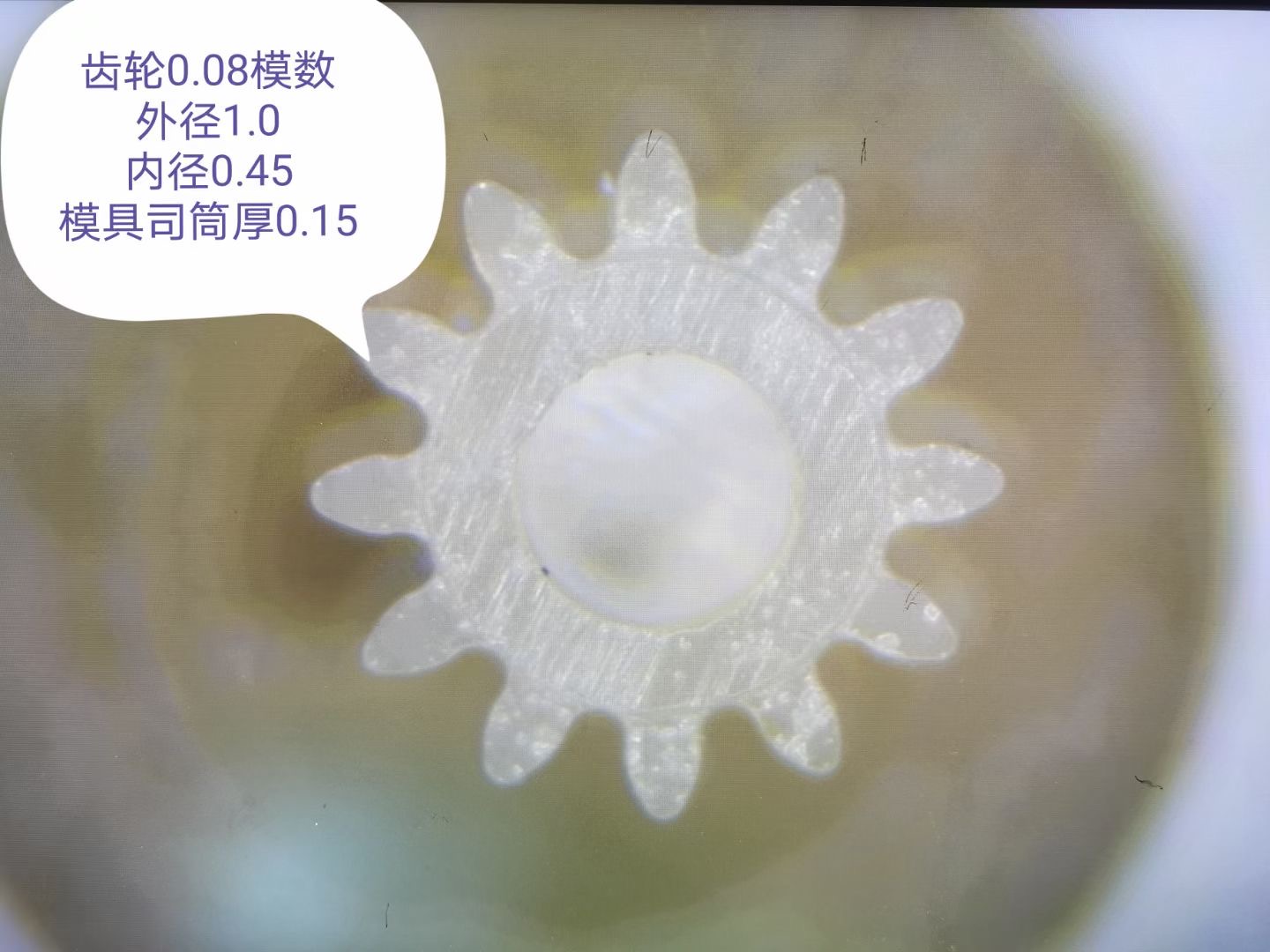

3.the smallest gear is M0.08 at current

4. 40 times stall test, the gear is no deformation, no damage, no noise

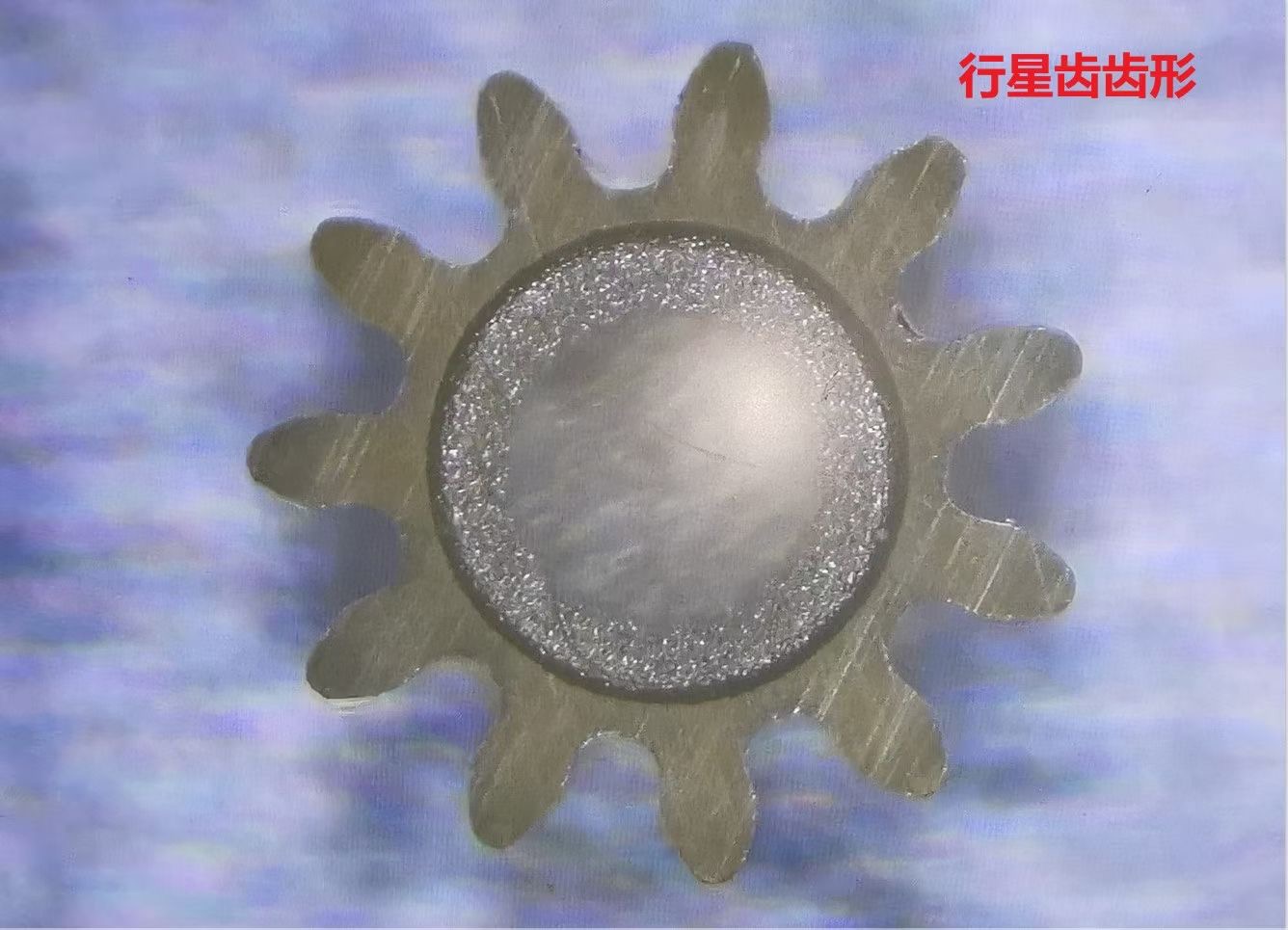

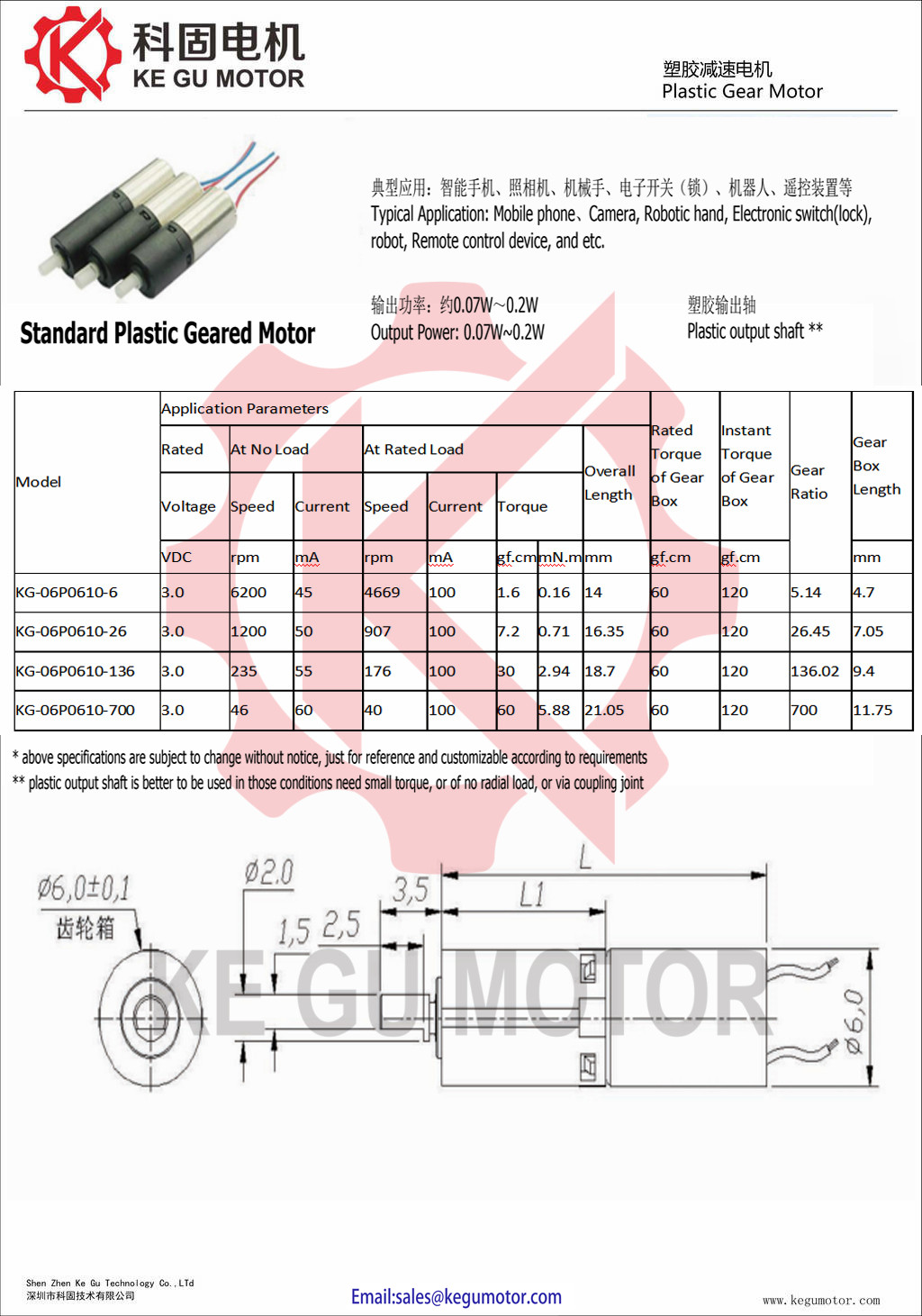

Kegu motor a manufacturer of miniature geared motors and has independently developed a 6mm diameter miniature geared motor. The outer diameter of this miniature geared motor is 6mm. It consists of a micro motor and a 6mm plastic gearbox, which contains planetary gears and planet carriers. The smallest planetary gear diameter is 1.4mm, and the modulus is 0.15. The gearbox has the characteristics of low noise and long service life. Suitable for corelss motors and stepper motors. The voltage range is 3-12V, and there are two directions of operation: CW and CCW. There are 4 types of 6mm miniature gear motors produced by Kegumotor, that is to say, there are 4 reduction ratios. The four reduction ratios are: 5.14; 26.45; 136 and 700. The specific parameters are shown in the figure below. Many readers will ask, how much is a 6mm miniature gear motor so small and precise? Different models have different prices, different MOQs have different prices.

Contact: Marketing Department

Phone: +86-18682260827

Tel: 0755-27801762

Email:sales@kegumotor.com

Add: 301, No. 12, Yaming Street, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen