Maintenance method for fatigue pitting of micro dc gear motor

Micro gear motor are widely used in our lives and are used in many industries. Undoubtedly, everyone pays a lot of attention to it. For example, we must understand the fatigue pitting corrosion factors of micro gear motors. Fatigue pitting is a common failure of planetary gear motor. After fatigue pitting occurs, the development speed is quite fast. If it is not found in time, it will cause large pieces of gears to peel off, which will lead to the scrapping of gears, and the gearbox can no longer be used. The gear motor supplier, then what are the solutions for the fatigue pitting of the planetary reducer? Let

Shenzhen Kegu Motor explain to you:

1. During the installation process of the reducer gear, the linear reduction motor company did not strictly implement the maintenance process, resulting in poor installation, causing partial contact of the tooth surface, and excessive load causing fatigue and pitting of the tooth surface;

2. The lubricating oil expires or deteriorates, the viscosity is too low or fails, so that an oil film cannot be formed between the tooth surfaces of the gears, and the direct contact between the teeth causes fatigue pitting on the tooth surfaces;

3. The use of the transmission bearing exceeds the limit or the clearance between the bearing and the bearing seat hole is too large, which causes the transmission bearing to vibrate too much and causes the load to increase, which causes the gear transmission load to increase, and it also causes the tooth surface fatigue pitting.

Micro geared motor, the countermeasures for fatigue pitting:

1. Intensify the training of personnel, operate strictly in accordance with the operating regulations, and ensure the reasonable use of the miniature geared motor, which is stable, accurate and fast. Moreover, in the operation process, prevent illegal reverse braking operation, avoid the permanent magnet DC motor motor gear contact stress increases instantly.

2. The geared motor factory must select reasonable materials and must undergo strict inspections. During the heat treatment of the materials, the heat must be uniform and the standards must be strictly implemented. Unqualified gears are not allowed to be used in production.

3. Strengthen the patrol inspection of the equipment. If there is any abnormality in the miniature geared motor, timely repair and adjust, timely replace the reducer's over-limit bearing, regularly check the anchor bolts, check the center of the gear coupling, and deal with any problems in time.

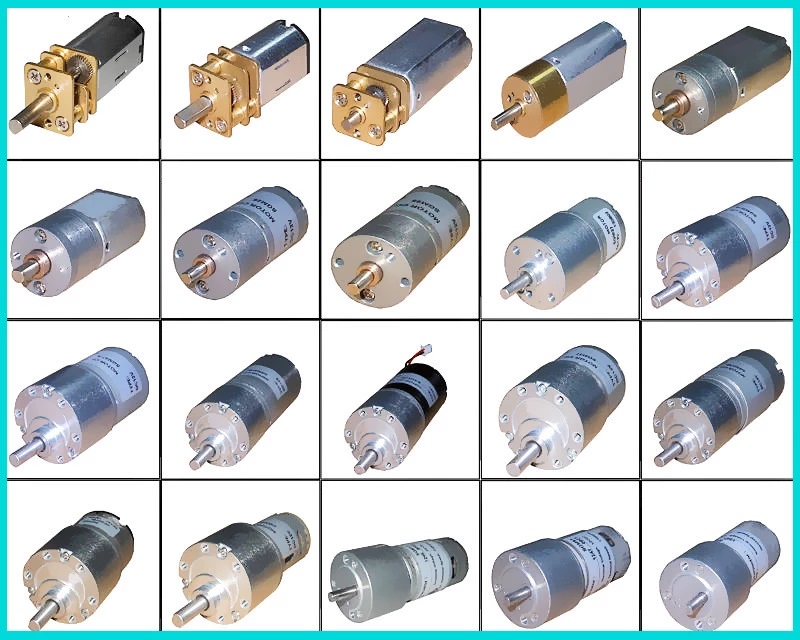

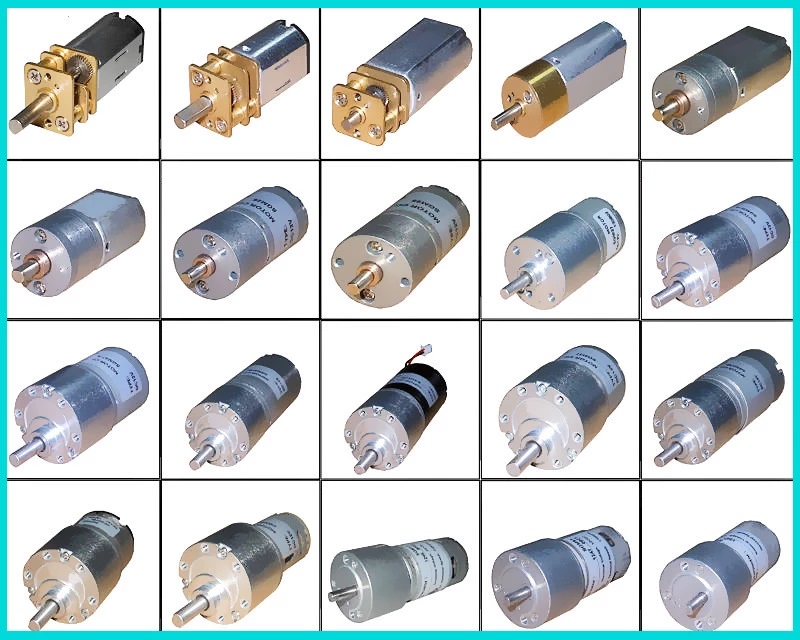

Shen Zhen Ke Gu Technology Co.,Ltd has designed and developed gearboxes, DC gear motors, miniature DC gear motors, planetary gear motors, reduction motors and other products through a large amount of experimental test data, which can effectively solve the problem of fatigue pitting in gear motors.